It leaks into our oceans, chokes waterways, and harms wildlife. Plastic waste—and the mismanagement of its disposal—has proven highly detrimental to people and the planet. We produce more than 350 million tons of plastic every year. Sadly, the vast majority of it ends up in landfills. The rest pollutes our oceans.

It isn’t plastics, though, that is the problem. It’s the insufficient solutions for plastic pollution that are so harmful. Plastic as a material has many benefits to modern society. It’s versatile, lightweight, and cheap. It also provides environmental benefits such as playing a critical role in maintaining food quality and reducing food waste.

Switching to non-plastic alternatives isn’t always the best solution, either. For instance, paper, aluminum, and glass have higher greenhouse gas emissions and use more energy, water, and fertilizer inputs than plastic. One of the better solutions to plastic waste pollution is creating sustainable plastics that can be recycled and repurposed over and over again.

Waste to Material to Reduce Plastic Pollution

If we’re to mitigate the dangers related to the waste crisis, effective management of all waste produced is an essential and urgent demand. While recycled plastic is a start, it is not a long-term solution. Most recycled plastics also eventually end up in landfills or are incinerated after one or two cycles. In fact, in the U.S., six times more plastic waste is burned than is recycled.

Plastic pollution prevention by way of a waste-to-sustainable thermoplastic solution is an efficient and cost-effective way to approach the waste crisis. UBQ Material takes unsorted waste and turns it into a premium eco-friendly thermoplastic that’s a substitute for conventional oil-based plastics.

UBQ is a waste conversion technology that converts all types of household waste into up-cycled bio-based materials. The process is known as waste valorization which simply means the reuse, recycling, or composting of waste materials to turn them into other products including materials, chemicals, and sources of energy.

The UBQ Material closed-loop process takes common household and food waste such as banana peels, plastic packaging, diapers, and other “unrecyclable” materials and reduces it into many of its basic natural components. These natural components then reconstitute themselves and bind together to form a new identical composite with thermoplastic properties. This new, upcycled composite can also be recycled over and again.

Solving the Plastic Pollution Challenge One Solution at a Time

Plastic is a worthwhile resource that offers real value. The challenge is in getting people to embrace the idea it can be just as valuable after it’s used. Only then will they be motivated to stop contributing to the gross mismanagement of plastic waste that causes so much harm to our rivers, forests, and oceans.

As a groundbreaking materials company, UBQ seeks to be a part of the greater plastic pollution solution, providing the missing link between waste disposal and new product manufacturing. Instead of extracting more of our finite natural resources, converting “trash into treasure” allows diverse industries to source and re-use waste materials already in circulation. The most climate-positive material available today, UBQ saves more emissions than are created in its production. The result? A negative net carbon footprint, an environmental benefit no other thermoplastic provides.

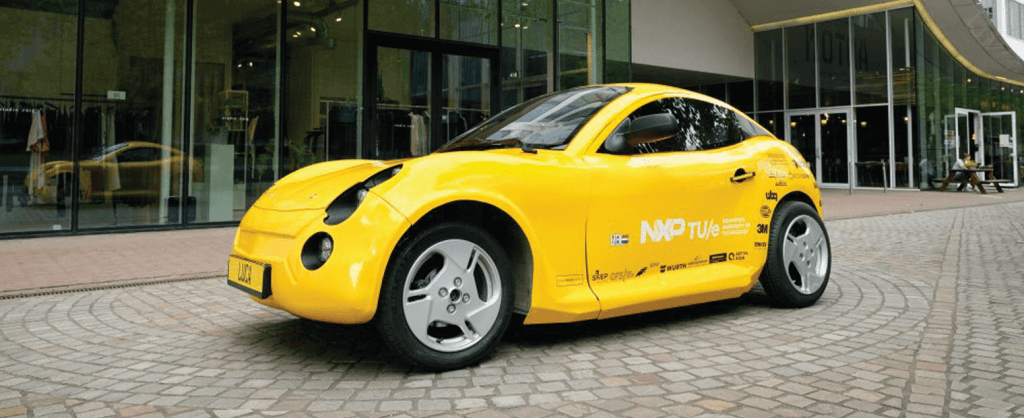

Clean, sustainable, and cost-effective, the thermoplastics produced with UBQ technology are the greenest thermoplastic material on the planet. Material waste can be used as a substitute for plastics, minerals, and wood in thousands of different applications including medical devices, automotive parts, and food packaging. Working closely with industry partners and with the support of investors and suppliers, our goal is to get others invested in a zero-waste approach that reduces emissions while accelerating the transition to a circular economy.

Get in touch with us today to learn more.