Standard plastics are made from polymers, long chains of carbon or hydrogen atoms that originate from petroleum or natural gases. Because these are not renewable energy sources, traditional plastic is not a sustainable material.

The global plastic waste problem is well-documented. In a world where nearly 360 million metric tons of plastic are produced each year, the consensus has been that plastics are an unsustainable material, and that only a few can be recycled. The reality is more nuanced, with a more significant issue being our linear economy model, where goods are produced, consumed, and disposed of. A circular economy model in which plastics are recycled and repurposed has so far been impractical and unprofitable.

Is it possible, then, for plastics to help build a sustainable future? Yes, and here’s how.

The Global Market Potential of a Sustainable Plastic

Plastics are ubiquitous in the global economy—imagining a world without them is nearly impossible. Plastics now make up roughly 15% of a car by weight and about 50% of a Boeing 787. They also offer a lot of benefits, including relatively low-cost production. There are, however, two significant environmental effects that flow from them:

- Current disposal methods, including landfills, have contributed to serious global health problems.

- Traditional plastic production depends on finite sources of fossil feedstocks.

With sustainability a top priority for many companies, industries and governments, the world of plastics is changing. New, sustainable alternatives to plastic, such as bio-based and biodegradable plastics, help divert bio waste from landfills and increase plastic waste management efficiency. The recycled plastic market size is expected to hit $72.6 billion by 2026, nearly doubling 2018’s $37.8 billion. Likewise, the global biodegradable plastics market is forecast to reach $8.57 billion by 2025. The bio-based plastics market is expected to grow from $10.5 billion in 2020 to $27.9 billion by 2025.

Much of the shift to sustainable plastic solutions is due to consumer awareness and preference for eco-friendly products. Tougher governmental legislation is also a driving force, as are stricter waste management regulations.

Sustainability From Waste

Perhaps “plastics” are not a problem at all but part of a pathway to a more sustainable way of life. A study by the Global Footprint Network found that working with heretofore unrecyclable waste to develop alternative plastic materials could reduce the current demand on the planet’s available resources.

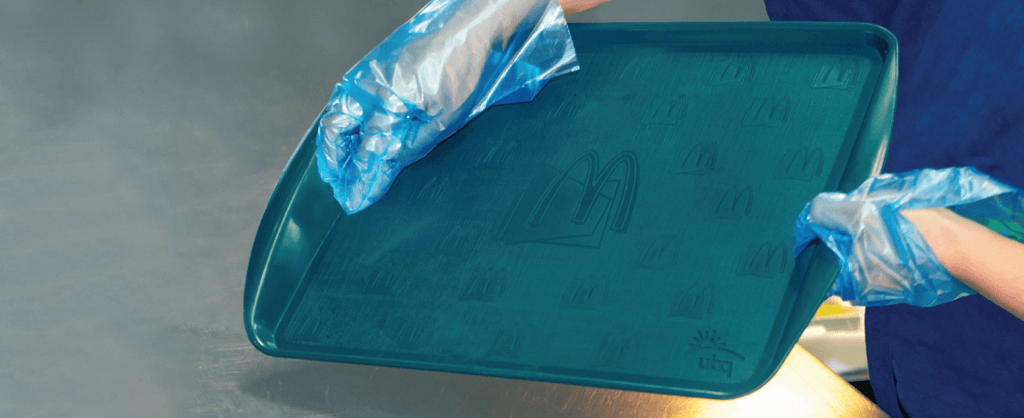

UBQ Material is one of the most promising advanced waste conversion technologies. Using a patented, closed-loop process, it transforms previously considered unrecyclable waste such as mixed plastics, food waste, cardboard, paper, and dirty diapers, and valorizes and converts it into a new, sustainable, raw material for the manufacturing of everyday familiar goods across a multitude of industries including the automobile, food service, and household good sectors.

Sustainable Solutions for Standard Plastic Material

To achieve broad adoption, sustainable plastic materials must:

- Preserve or build on the original material’s performance.

- Be competitively priced.

- Have genuine advantages that support making the switch.

Most importantly, from a production standpoint, they must be capable of being used in existing manufacturing processes without significant, additional adaptation costs.

Beyond price parity and seamless integration, UBQ Material’s competitive advantage is its ability to bring a powerful environmental value proposition: a net-zero, climate-positive impact. The UBQ process uses relatively small amounts of energy and no production waste, effluents, or water use. It also prevents the emission of methane, groundwater leakage, and other toxins. The result is a circular economy model that will eventually eliminate the need for landfills while conserving finite resources for future generations.

A remarkable and sustainable alternative plastic material, UBQ™ can be applied to substitute not only for plastic but wood, concrete, and metal. Entirely organic and completely recyclable, UBQ Material is designed to reduce harmful GHG emissions while helping manufacturers reduce their global footprints.

Hopefully, increasing public pressure, together with government and industry support, is turning the tide towards a circular reality. That bodes well for a wider acceptance of alternative plastic initiatives, which can lead to a cleaner and more sustainable planet for future generations.