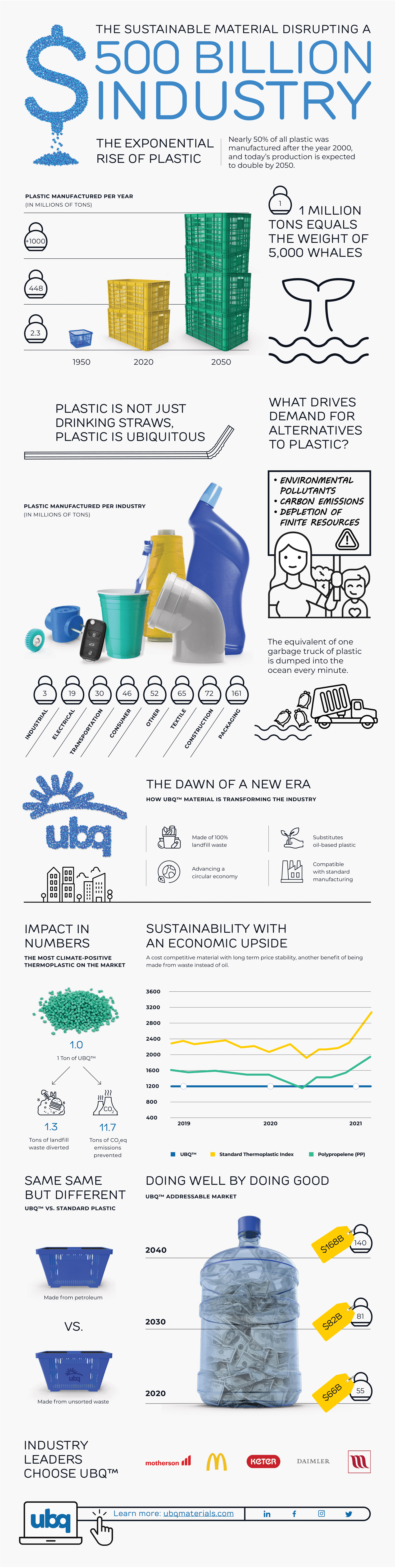

Plastic production is on the rise and fossil fuels continue to make up the majority of their feedstocks. Plastic is not just drinking straws; plastic is everywhere – laptops, pipes, appliances, cars, car keys, to name just a few.

If we look around us at the things we have purchased and things we use in our every-day routine, we would undoubtedly notice that plastic has forever changed the way we live. Plastic is not going anywhere, and if we continue business as usual, plastic production is expected to reach over 1 billion tons per year by 2050.

The benefits of plastic can’t be denied, but sadly, neither can their environmental impact. Consumers are demanding plastic alternatives and end of life solutions, and manufacturers want to follow suit. Not only are plastic producers looking for sustainable plastic alternatives, but they are also feeling the effects of a resin price increase. Plastic raw material prices are soaring, with resin prices rapidly increasing due to a decrease in availability. However, the future is not as gloomy as it seems… innovative solutions do exist!

At UBQ Materials, it’s the dawn of a new era for sustainable manufacturing. UBQ™ is a climate-positive thermoplastic made entirely of unsorted landfill waste, including all organics and unrecyclable plastics. A seamless drop-in material, UBQ™ is compatible with today’s standard manufacturing processes, able to substitute oil-based plastics and advance a circular economy.

UBQ’s waste recycling technology diverts landfill waste, prevents landfill emissions, and protects finite natural resources for future generations. Being made from waste instead of oil, this climate-positive thermoplastic is cost competitive to oil-rich plastics and offers long-term price stability, allowing manufacturers to meet their sustainability goals without compromising on profitability.

Want to learn more about UBQ and how it’s disrupting the $500 billion plastics industry? Check out the infographic below and share with your network!