Key Takeaways:

- UBQ™ is a pioneering material made from municipal solid waste, offering a climate-positive solution for sustainable construction.

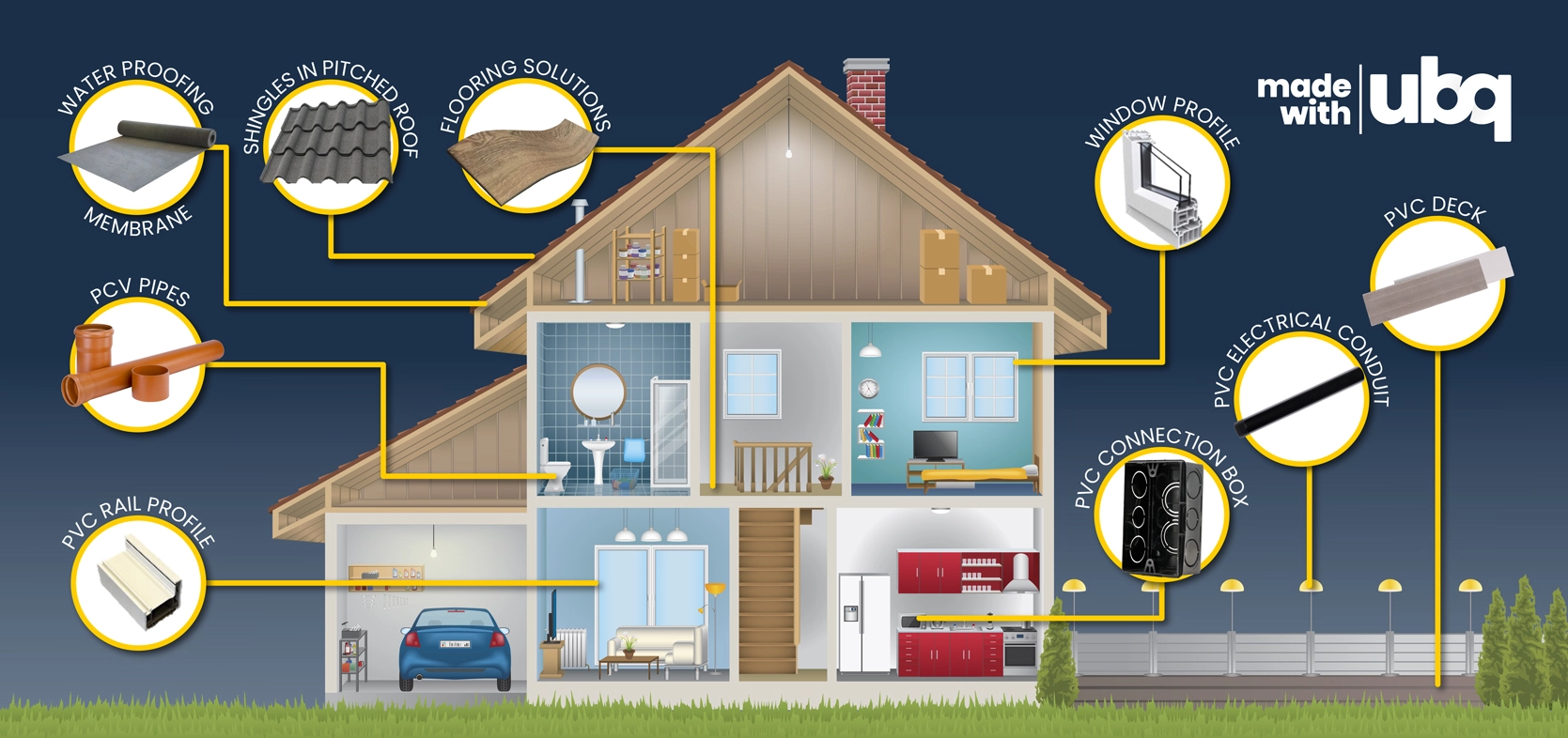

- Tested and tried applications include bitumen roofing membranes, luxury vinyl flooring, fencing, window profiles, protective profiles, WPC benches, PVC connection boxes, and PVC electrical conduits.

- Circular and recyclable, UBQ™ reduces carbon footprints, removes greenhouse gas emissions, and advances sustainability targets in construction projects.

A Game-Changer for Sustainable Construction

Currently, the buildings and construction sector is the largest emitter of greenhouse gases, accounting for a staggering 37% of global emissions. In response, the World Green Building Council has set an ambitious goal: a 40% reduction in embodied carbon for new and renovated buildings by 2030, with the ultimate target of achieving net-zero embodied carbon by 2050. Achieving zero-carbon buildings is not only feasible but also economically viable with the addition of UBQ™, a sustainable, bio-based material that can be integrated into applications ranging from flooring to roofing and beyond, significantly lowering the carbon footprint of modern building structures.

The future of construction is circular, sustainable, and waste-free. UBQ Materials is at the forefront of this transformation with UBQ™ material, an innovative, bio-based composite that can replace plastics in conventional building materials. Created from 100% unsorted household waste, UBQ™ diverts trash from landfills and incinerators and transforms it into climate-positive material that can be integrated into multiple applications for building and construction purposes.

Builders, architects, and manufacturers are constantly looking for ways to reduce carbon emissions while meeting performance requirements and maintaining cost efficiency. UBQ™ delivers on all fronts, offering a scalable and climate-positive solution that does not compromise performance, and it is not impacted by the oil price market fluctuation. With applications ranging from structural components to finishing elements, UBQ™ is offering building and construction companies a way to accelerate the achievement of their sustainability targets.

What is UBQ™?

UBQ™ is a bio-based, thermoplastic composite made from mixed household waste, including all organics and hard-to-recycle materials. UBQ™ can be used as a material replacement to conventional virgin and recycled plastics in durable and semi-durable applications.

UBQ™ is highly recyclable, promoting resource conservation and advancing the circular economy. Tests by Axion Polymers (former Axion Group) show that adding UBQ™ to durable and semi-durable applications doesn’t affect the mechanical properties of recycled plastics during reprocessing.

UBQ™ as a Sustainable Construction Material

UBQ™ is revolutionizing the construction industry by replacing conventional materials with a low-carbon, cost-effective, and circular alternative. Its benefits extend far beyond sustainability, offering builders and manufacturers a high-quality, resilient material that integrates into existing processes and meets performance requirements

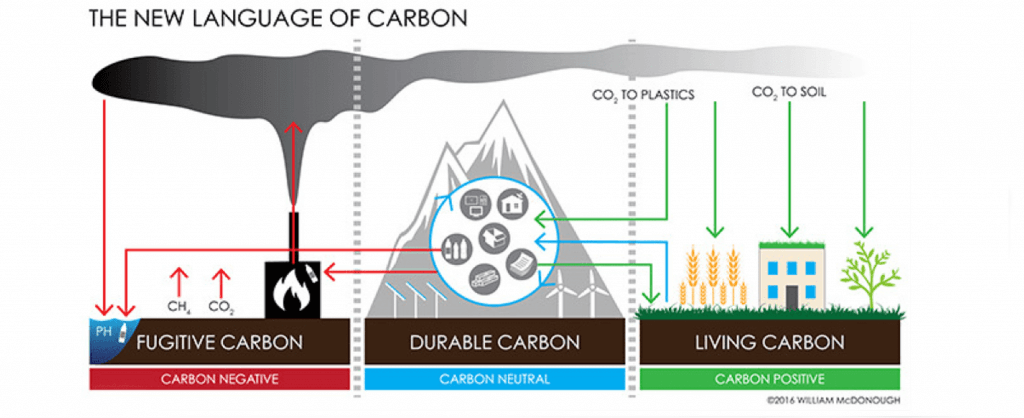

The construction industry could benefit from bio-based materials, though not all are equally sustainable. First-generation feedstock for biobased materials are primarily made from crops like corn, wheat, and sugarcane, which raises concerns about competing with food supplies and contributing to global scarcity. Cultivating these crops demands considerable land and water resources.

Second-generation feedstocks for biobased materials, derived from agricultural waste, have faced similar challenges. Although they require additional processing to extract fermented sugars, there are concerns about the use of edible oils impacting food resources and contributing to deforestation.

Third-generation feedstocks, such as waste, are making significant strides. By effectively converting waste into a bio-based thermoplastic material, the building and construction industry can replace fossil fuel-based plastics with a circular, carbon-negative alternative like UBQ™.

Where Can UBQ™ Be Used in Construction?

- Bitumen Roofing Membrane

- Luxury Vinyl Flooring

- Flooring

- Window Profiles

- Protective Profiles

- WPC Bench (Wood Plastic Composite Bench) – McDonald’s Brasil has integrated UBQ™ into their first sustainable restaurant in São Paulo, using it in high-density polyethylene-based WPC benches.

- PVC Connection Boxes – Used in McDonald’s sustainable restaurant in Brazil, these connection boxes contribute to enhancing the sustainability of the restaurant.

- PVC Electrical Conduits

Performance and Benefits

✔ Circular and recyclable: UBQ™ keeps waste out of landfills and incinerators while maintaining full recyclability.

✔ Compatible with existing processes: UBQ™ is compatible with existing processes, polymers and equipment.

✔ Versatile across applications: UBQ™ replaces conventional materials like plastic, wood, and other polymers in construction, infrastructure, and interior design.

✔ Reduces environmental impact: UBQ’s advanced solution reduces greenhouse gas emissions, decreases reliance on conventional plastics, and minimizes the need for natural resource extraction

UBQ™ vs. Traditional Materials: Why It’s a Better Choice

| Feature | UBQ™ Material | Conventional Plastics |

| Sustainability | 100% household waste, circular & recyclable | Fossil-based, contributes to pollution |

| Carbon Footprint | Climate-positive, removes CO₂ & methane emissions | High carbon footprint, energy and water-intensive |

| Performance | Meets performance requirements | Varies, often needs additional treatment |

| Manufacturing Compatibility | Compatible with existing processes, polymers, and equipment | Requires specific infrastructure |

| Cost Stability | Price stability due to waste-based feedstock | Prices fluctuate with oil and resource scarcity |

Looking Ahead: UBQ™ and the Future of Construction With Sustainable Construction Materials

As governments and corporations intensify efforts to decarbonize the built environment, the demand for alternative, sustainable materials is surging. UBQ™ presents a groundbreaking opportunity for architects, engineers, and manufacturers to lead the way in the building revolution.

With building regulations evolving to favor low-carbon and recyclable materials, UBQ™ positions itself as a future-proof choice. From urban infrastructure to residential projects, integrating UBQ™ into construction projects means making an active impact on sustainability goals while keeping innovation and efficiency at the forefront.

Looking Forward

As the demand for sustainable construction materials continues to rise, UBQ™ stands at the forefront of construction, offering an innovative and sustainable alternative to traditional construction materials.

For construction professionals aiming to reduce greenhouse gas emissions and embrace sustainable building practices, UBQ™ offers a sustainable building material that not only diverts waste from landfills but also minimizes reliance on natural resources like natural aggregates and reclaimed wood.