The main objective of the JTF is to enable regions heavily dependent on income and employment from fossil fuels to undergo an energy transition in a fair and equitable manner. This transition takes into account social, economic, and environmental aspects.

The West-Noord Brabant region is home to one of the largest chemical industries in the country. However, with the increasing focus on the transition to a circular economy, the fossil industry is declining and with it, the number of jobs in this sector. Five of the fifty largest CO2 emitters in the Netherlands are located in West-Noord Brabant, which means that the region will be impacted by the energy transition and needs to prepare for its socioeconomic and environmental effects.

UBQ Materials has developed an advanced innovative waste conversion technology; patenting a pioneering bio-based thermoplastic composite (UBQ™) made entirely of municipal unsorted household waste, including all the organics and hard-to-recycle materials.

UBQ Materials was founded in 2012, when the company developed and patented a process to convert mixed municipal solid waste, including organics, into a thermoplastic material known as UBQ™. The proprietary and patented product and manufacturing method were developed, tested, and validated between 2012 and 2017.

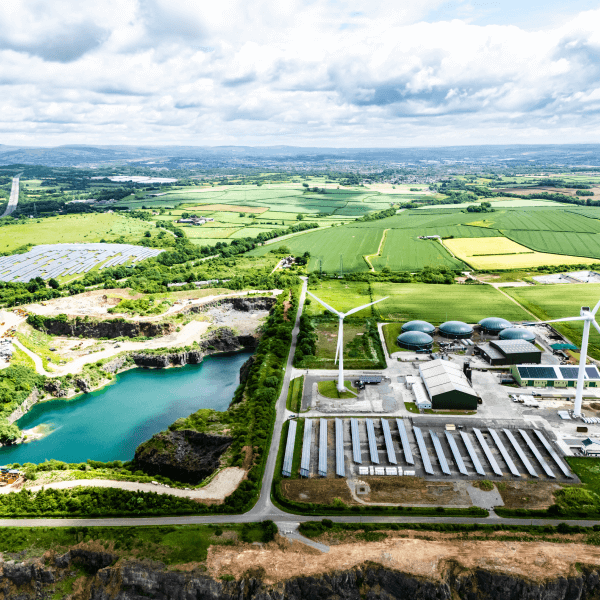

In 2024, the company opened a full-scale production facility in Bergen op Zoom, the Netherlands. The plant can process more than 104,600 tonnes of municipal solid waste annually, converting it into up to 80,000 tonnes of UBQ™.

The Israel plant is now being used as a Research & Development facility.

Successfully demonstrate and validate the innovative UBQ-conversion process.

Make the factory even more energy-efficient through an energy monitoring system to review how output can be increased.

Continue the UBQ product portfolio development process.

An even more advanced and further improved energy-efficient, demonstrational and scalable plant in Bergen op Zoom, The Netherlands with a capacity to convert 104.600 tons of regional waste into its novel bio-based thermoplastic composite, UBQ™.

The UBQ facility in Bergen op Zoom has been designed to be resource efficient, modular, and scalable, using multi-line layout capacity, paving the way for mass production and global expansion of UBQ.

Currently, UBQ Materials works with companies in the consumer durable, supply chain and logistics, automotive, and building and construction sectors.